Jim Krenov’s machines, the ones written about and pictured in “The Fine Art of Cabinetmaking” have a new home with Robert Van Norman who operates the Inside Passage School of Fine Cabinetmaking in Roberts Creek, British Columbia. Jim Krenov is most known for his use of hand tools and a caring attitude to create fine and creative small cabinets each one a treasure, but because of Jim’s writing about his measured use of these four finely produced machines through his years in Sweden, they, too, are a part of his legacy. When he moved from Sweden he brought his Stenbergs machines with him and they were part of the machines used by students in the Fine Wood Working Program he started in Fort Bragg, California. As the years passed Jim did not wish this level of use day in and day out on the machines and they were removed as other machines were acquired by the school.

Twenty-nine years ago Jim told me he was thinking of selling his machines and wondered if I wanted any of them. I told him I thought he should not sell them but keep them for the day he might to longer teach at the Fort Bragg school and would have another shop of his own. A week later we repeated this conversation and then when asked for the third time I answered that if I were going to purchase his machines that I would like to purchase all of them. Jim said he was hoping that is what I would say. When the transfer was made it was with great reverence for these machines but Jim was clear that they were mine with no commitment as to their future.

I have long thought Jim’s machines at their best should be part of student’s inspiration in learning the craft of fine cabinetmaking that Jim practiced and spoke about with such rare elegance. Using Jim’s machines was a treasure to me every day but they no longer filled my dream of the machines being close to aspiring students. I knew Robert Van Norman was the right person for these machines and every communication I had with him and his wife, Yvonne, clarified the decision. Jim Krenov’s wife, Britta, said Jim would love the machines moving to Robert where they would be close to the students at the Inside Passage School.

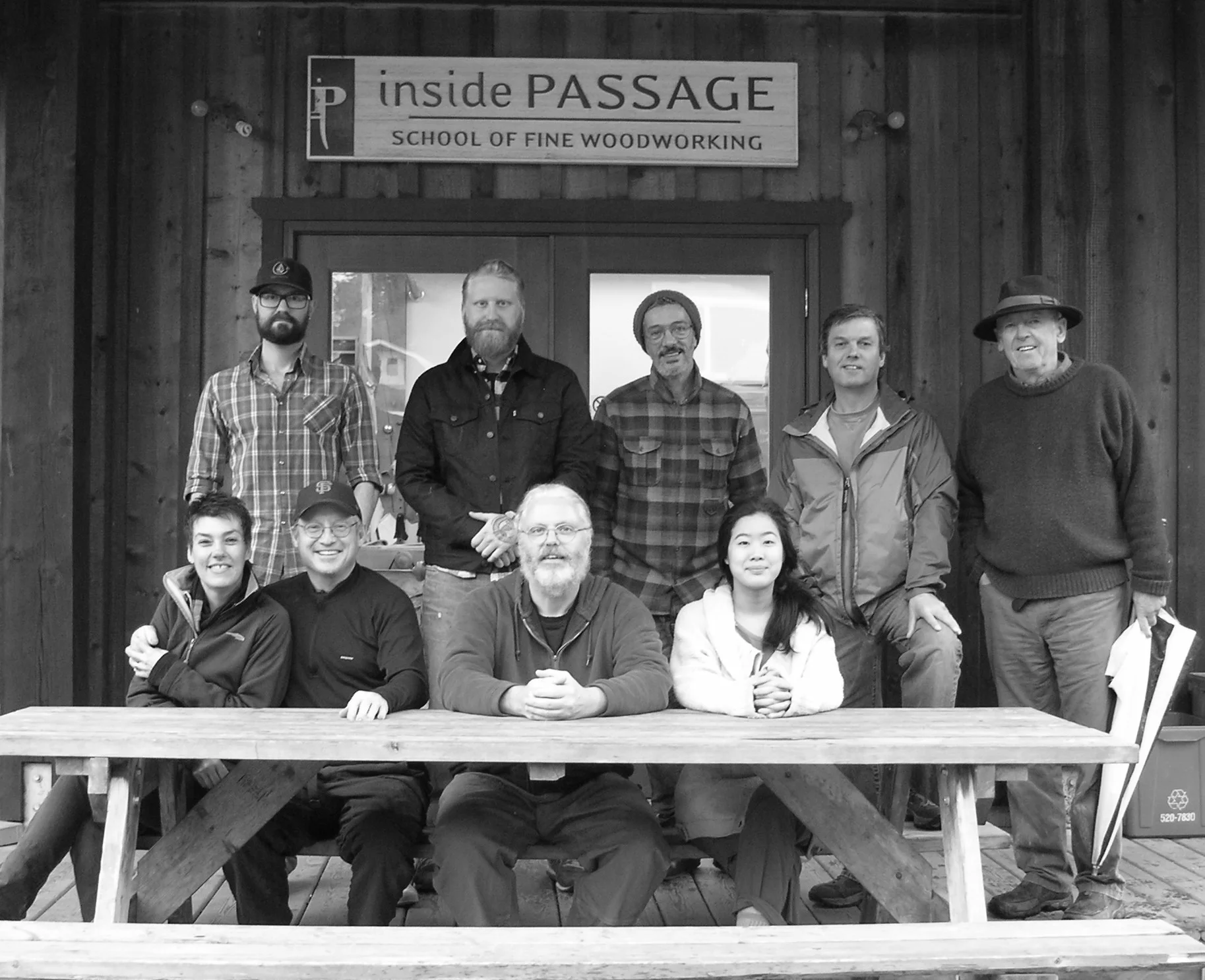

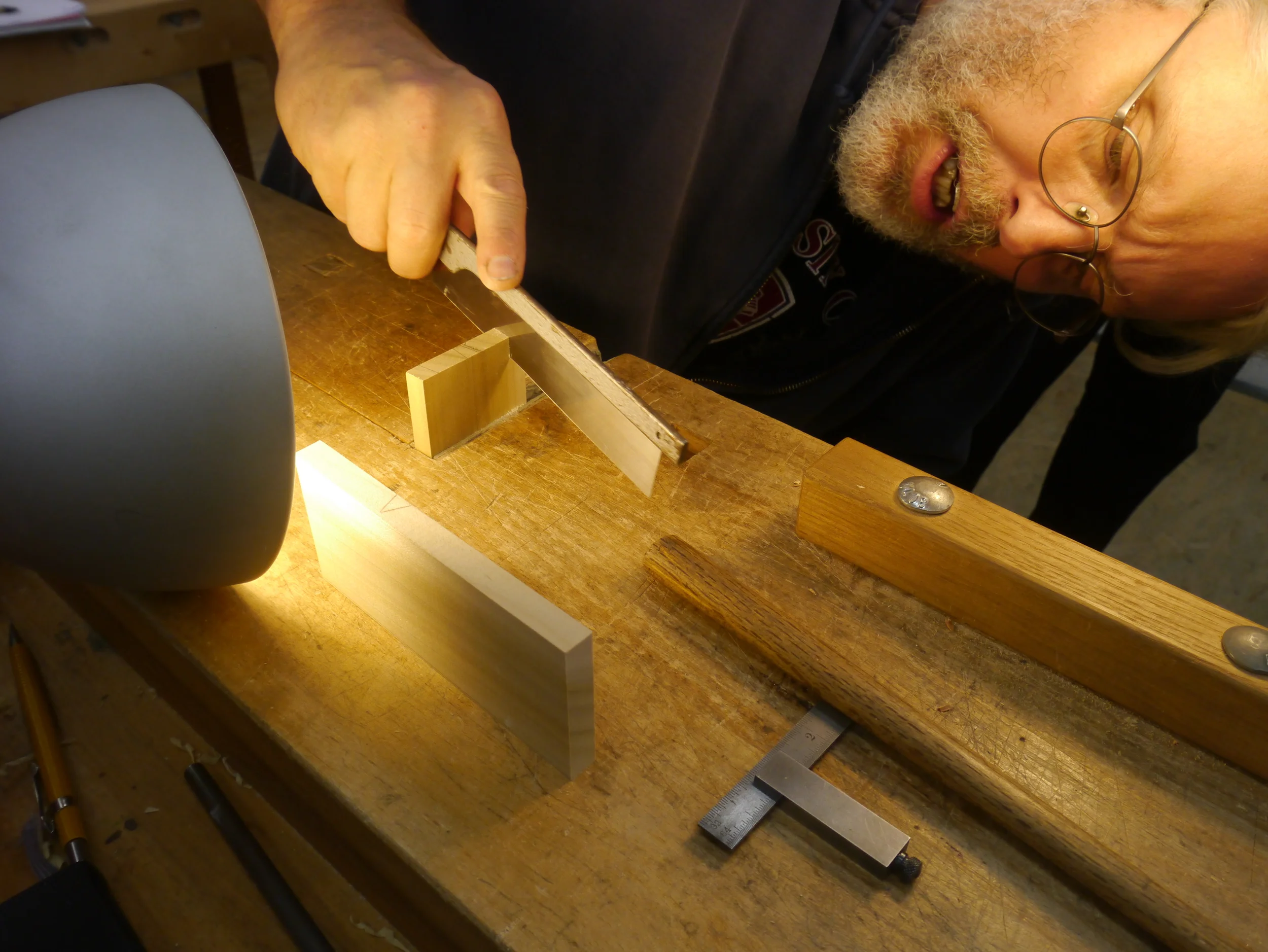

My wife, K., and I entered the quaint picturesque village of Roberts Creek along the Sunshine Highway in British Columbia to a reception we will never forget. Large black and white pictures of Jim working at his bench hung on the walls of the Inside Passage School benchroom as students worked. Robert Van Norman has created a setting where the very best of Jim Krenov’s spirit lives on. Everyone walked to Robert’s home to help unload the machines. I gave Robert my copy of The Fine Art of Cabinetmaking in which Jim had written a little note to whoever might care for these machines in the future. I shared memories as his student during the third and forth year of his teaching at the woodworking program in California. A cabinet on the wall of Robert’s small shop contained many of Jim’s hand tools and I thought it must feel somewhat like Jim’s small basement shop in Sweden. Robert and Yvonne’s sole use of public transportation reminded me of Britta saying how she had not learned to drive until they moved to California. Another picture of Jim Krenov had a caption from his writing, “Ours is a simple craft. But it is a rich one, too. At its best, the simple becomes obvious: a band of small discoveries, strung like pearls of curiosity, lending richness to our work.”

Reading Jim Krenov’s first book, A Cabinetmaker’s Notebook, I knew immediately I wanted to train with Jim who had trained with Carl Malmsten of Sweden who had trained with Edward Barnsley of England. After graduating from the Fine Woodworking Program in Fort Bragg, California, I felt a part of a linage of fine craftspersons who created their own work while passing the inspiration and skill to the next generation. Robert Van Norman also trained with Jim at the same program in California and is now dedicating his life to passing his own and Jim’s skills and inspiration to a new generation of fine furnituremakers. Students from around the world work at the Inside Passage School of Fine Cabinetmaking with the same enthusiasm for their training with Robert that I remembered from my training thirty years earlier with Jim. The machines having moved to this school are now a part of inspiring the next generation.

Monroe Robinson

Woodworker and purveyor of fine old growth redwood lumber in Little River, California